- Home

- »

- Concrete Plant

CONCRETE PLANT

Concrete batching plants are facilities used in the production of concrete used in the construction industry. Concrete is a widely used building material in the construction industry and is used in many structures such as buildings, roads, bridges, dams and ports. Concrete batching plants are facilities where concrete is produced by mixing various components. These ingredients are usually cement, water, sand, gravel and sometimes additives. Concrete plants produce high quality concrete by mixing these components with a certain proportion.

Concrete batching plants can be either fixed or mobile. Fixed concrete batching plants are generally used in large construction projects and are permanent. Mobile concrete batching plants, on the other hand, are a solution used in portable and short-term projects. Concrete batching plants use various technologies to improve the quality of concrete. These technologies include methods such as automatic weighing, automatic mixing, control of concrete temperature and humidification. Thanks to these technologies, the quality and durability of concrete are increased.

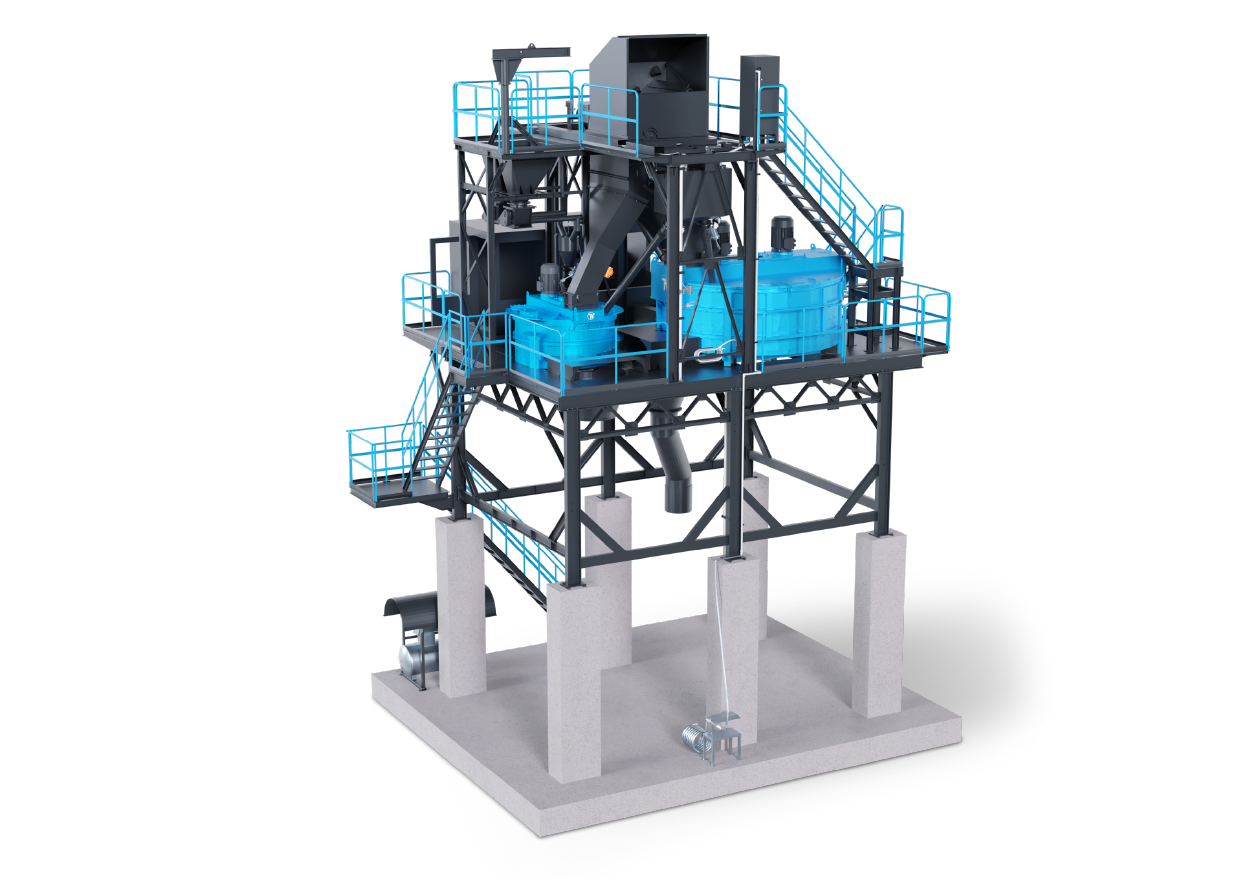

Stationary Concrete Plant

Such power plants are generally used in large construction projects. Stationary concrete plants are a permanent facility where the components used for the concrete mix are mixed and produced. These facilities usually use stationary concrete mixers. Fixed concrete batching plants are facilities where concrete is produced by mixing cement, aggregate (sand, gravel, stone), water and additives in the right proportions. Fixed concrete batching plants include basic components such as concrete mixing unit, aggregate feeding system, cement silos, water supply system and control system. Some stationary concrete plants may also have additional components, for example automatic concrete dosing systems and concrete mixing tanks. Fixed concrete batching plants are a suitable option especially for large-scale construction projects, as they have high production capacity and provide operational efficiency with automatic control systems. Stationary concrete batching plants are also used in special projects, for example the construction of high-rise buildings or large bridges. Fixed concrete batching plants are designed to produce high quality concrete and ensure that the produced concrete is homogeneous. In addition, stationary concrete batching plants contain specialized personnel and equipment that can perform laboratory tests to check the specific properties of the concrete produced. Disadvantages of stationary concrete batching plants are that they have a fixed location, so they can be difficult to transport to the construction site. In addition, stationary concrete batching plants are not suitable for small-scale projects or businesses due to their high investment and operating costs.

- Pi 60 BTS ( 60 m³/s )

- Pi 100 BTS ( 100 m³/s )

- Pi 120 BTS ( 120 m³/s )

- Pi 180 BTS ( 180 m³/s )

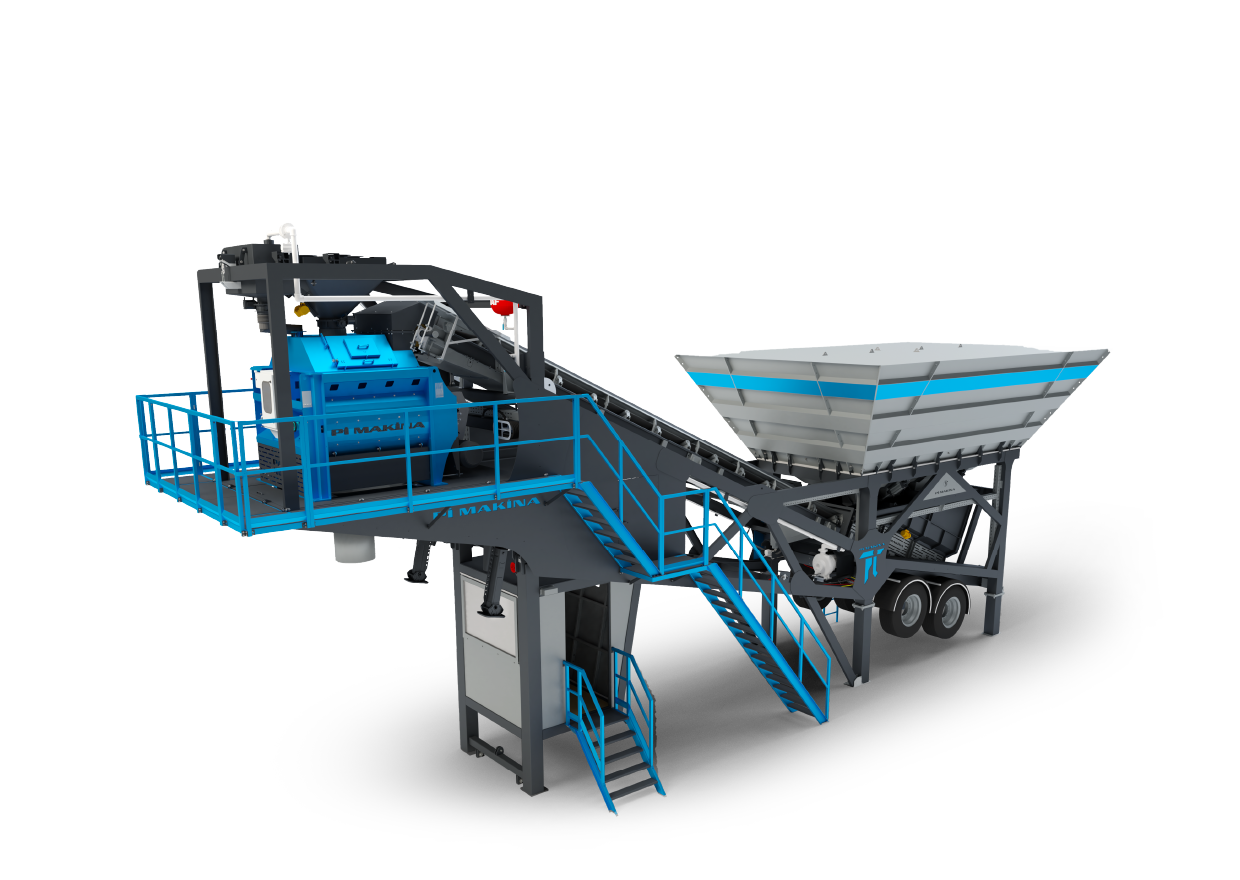

Mobile Concrete Batching Plant

Such power plants are portable and environmentally friendly at the construction site. Mobile concrete batching plants are ideal for short-term construction projects. These facilities have a smaller capacity than fixed concrete plants. mobile concrete batching plants are portable and facilities that can produce concrete in operation areas. They are generally used in the construction industry and can be of different sizes. Mobile concrete plants generally include basic components such as concrete mixing unit, aggregate feeding system, cement silos, water supply system and control system. Some mobile concrete batching plants may also have additional components, for example an additive feeding unit or an automatic concrete dosing system. One of the biggest advantages of mobile concrete batching plants is that they are portable. This makes them easy to use on construction sites where concrete is needed. In addition, mobile concrete batching plants provide lower investment costs and operating costs compared to central concrete batching plants. Besides, it is ideal for mobile concrete batching plants, small businesses and special projects. Mobile concrete batching plants are also very reliable in terms of the quality of the concrete they produce. The concrete produced by these facilities using modern technologies stands out with its features such as high strength, durability and low water permeability. However, mobile concrete plants must comply with local legal regulations due to some environmental factors such as landscaping and emission control. In addition, mobile concrete plants may also need some infrastructure requirements such as access to suitable water resources and energy resources at the operation site.

- Pi 60 MTS ( 50-60 m³ )

- Pi 100 MTS ( 90-100 m³ )

- Pi 120 MTS ( 120-130 m³ )

- Pi 60 MSP ( 50-60 m³ )

- Pi 55 M-ECO ( 50-55 m³ )

- Pi 100 MB ( 90-100 m³ )

- Pi 120 MCB ( 120-130 m³ )

- Pi 100 MTS+ ( 90-100 m³ )

- Pi 120 MTS+ ( 120-130 m³ )

Mini Concrete Plant

Mini concrete batching plants are mobile plants that produce concrete for small-scale construction projects. These plants are ideal for customers who need concrete especially in tight spaces, with limited budgets or for small construction projects. Mini concrete batching plants are operated by small businesses that focus mostly on concrete production. These plants produce the concrete mix using materials such as cement, water, sand and aggregate. The quality and properties of concrete depend on the quality, quantity and ratio of the materials used. Mini concrete batching plants are small facilities that can be easily transported and brought to the construction site. By increasing the quality of concrete used in small construction projects, it increases work efficiency and reduces costs. In addition, mini concrete batching plants can be an ideal solution for such projects, as it is not possible to use large-scale batching plants when working in tight spaces or places with difficult access.

- Pi 30 FT ( 25-30 m³ )

- Pi 30 FTX ( 25-30 m³ )

- Pi 30 FT+ ( 25-30 m³ )

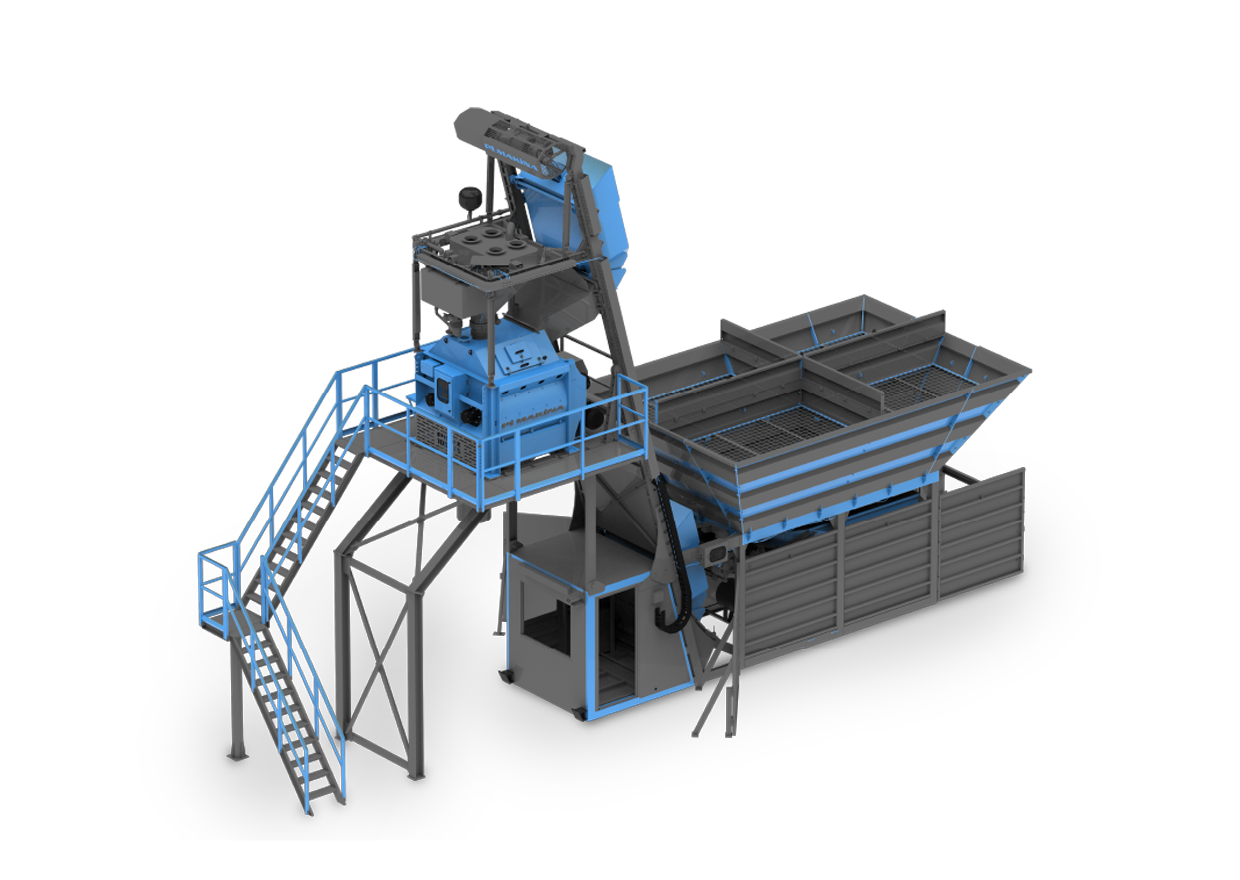

Compact Concrete Batching Plant

Compact concrete batching plants are considered as a kind of concrete production plant located between mobile and stationary concrete batching plants. Compact concrete plants can be transported similar to mobile concrete batching plants and can produce high-capacity concrete similar to stationary concrete batching plants. Compact concrete batching plants can be easily transported and installed thanks to their modular design. These facilities are ideal for rapid on-site production of concrete and are also suitable for small-scale projects, temporary construction sites and tight workspaces. Compact concrete batching plants include basic components such as concrete mixing unit, aggregate feeding system, cement silos, water supply system and control system, similar to mobile concrete batching plants. In addition, some compact concrete plants may have additional components such as concrete dosing systems and automatic control systems. Compact concrete batching plants provide lower investment costs and operating costs compared to stationary concrete batching plants. In addition, they can have a higher capacity compared to mobile concrete plants and can be used in sustainable construction projects due to their environmental friendliness. The disadvantages of compact concrete batching plants are that they have less capacity compared to stationary concrete batching plants and that they are less portable than mobile concrete batching plants. In addition, compact concrete plants do not provide high production capacities like stationary concrete batching plants. In conclusion, compact concrete plants are a concrete production plant option that balances portability and production capacity. Depending on the characteristics of the project, mobile concrete batching plants, stationary concrete batching plants or compact concrete batching plants can be preferred.

- Pi 30 CP

- Pi 60 CP

Precast Concrete Plant

Precast concrete plants are facilities where precast concrete products used in the production of reinforced concrete structural elements are produced. In these plants, reinforced concrete structural elements can be produced in series using pre-prepared molds of various sizes. Precast concrete batching plants use the method of mounting reinforced concrete structural elements produced in the factory environment by bringing them to the construction site. In this way, while the construction period is shortened, work efficiency is increased and costs are reduced. These power plants are generally used for high-volume production and are preferred in large-scale construction projects. Precast concrete plants are equipped with molds of different sizes and shapes, which are suitable for the production of various building elements. These elements can include many structural elements such as wall panels, beams, columns, floor slabs, stairs, roof panels, drainage channels, water tanks and tunnel segments. Precast concrete batching plants are generally equipped with high-tech automation systems. These systems are used to control all production processes such as preparing the concrete mix, filling the molds, vibration, temperature control, mold removal, surface treatment and packaging. As a result, precast concrete plants are modern facilities that enable the mass production of high quality, durable and aesthetically attractive reinforced concrete structural elements.

- Pi 100 BPS ( 100 m³/s)

- Pi 100 BP ( 90-100 m³/s )

- Pi 60 BP ( 60 m³/s )

- Pi 30-100 BP ( 120 m³/s )

- Pi 30-60 BP ( 60 m³/s )

About Concrete Pump

Concrete Batching Plant Prices?

Concrete Batching Plant prices are determined depending on many factors, and these factors include the following: Capacity: The

Safety Measures in Concrete Batching Plants

Concrete Batching Plants are facilities where concrete is produced and rendered ready. Safety during concrete production is critical

Service And Maintenance Of Concrete Batching Plant

Concrete batching plants entails regular maintenance. Maintenance is critical to extend the operating life of the plant, improve

How To Install a Concrete Batching Plant

Concrete batching plants installation is a rather complex process, and many factors must be considered. You can find

What Are The Types Of Concrete Batching Plant?

Concrete batching plants can be of different capacities and characteristics. Choosing the most suitable concrete batching plant according

What Are The Components Of a Concrete Batching Plant?

Concrete batching plants are facilities employed in the production of concrete used in the construction sector. Concrete is

What is a Concrete Batching Plant?

Concrete batching plants are facilities employed in the production of concrete used in the construction sector. Concrete is

Concrete Batching Plant Installation

Concrete Batching Plants are installed by the manufacturer company unless the customer requests otherwise. Pi Makina, which has

Superior Features of Pi Makina Concrete Batching Plants

1-) Pi Concrete Batching Plants are designed to operate under heavy conditions and in different climatic conditions, have

Concrete Plant Eqiupment

Concrete; It is a material that is formed by a mixture of cement and water that holds aggregates

Concrete Plant Main Chassis

The main unit includes “Mixer”, “Weighing Group”, “Aggregate Holding Bunker” and other auxiliary equipment as standard. a-) Weighing

Concrete Plant – Automation System

The automation system, which is the most important unit of concrete batching plants; In addition to panel control,