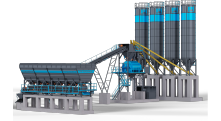

- Concrete Batching Plants

- Stationary Concrete Plant

- Mobile Concrete Plant

- Mini Concrete Batching Plant

- Compact Concrete Batching Plant

- Precast Concrete Batching Plant

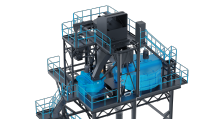

- Concrete Mixer

STATIONARYConcrete Batching Plant

MOBILEConcrete Batching Plant

MINIConcrete Batching Plant

COMPACTConcrete Batching Plant

PRECASTConcrete Batching Plant

MIXERConcrete Mixer

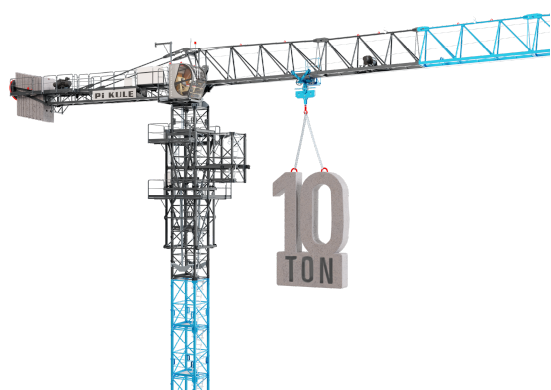

- Concrete Distribution Group

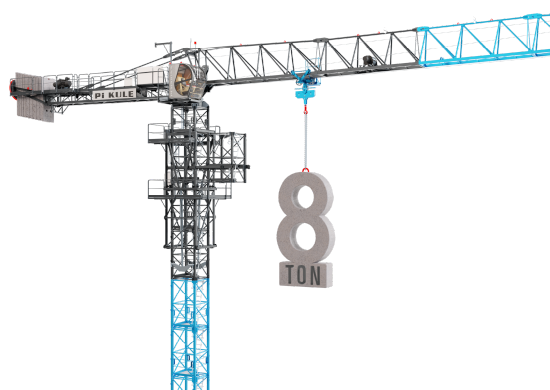

- Tower Crane

TOWER CRANE

10 Tons

TOWER CRANE8 Tons

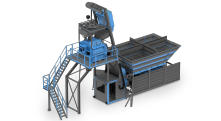

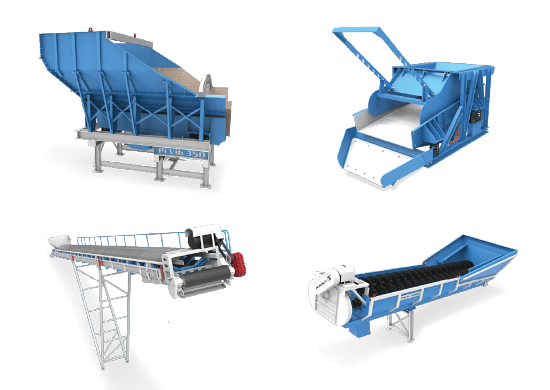

- Crushing Plant

CRUSHER

Crushing Plant

CRUSHING EQUIPMENTCrushing Plant

- Earth Moving Machine

MOTOR GRADER

Earth Moving Machine

BACKHOE LOADEREarth Moving Machine

English

What Are The Components Of a Concrete Batching Plant?

Concrete batching plants are facilities with a complex structure and include many components:

Aggregate Bunkers : These are the storage units where sand, gravel and other aggregates are stored.

Conveyor Belts: These are the belts used for the transportation of aggregates from storage areas to concrete plants.

Weighing Systems: These are the systems where components such as sand, gravel, water, and cement are weighed in the proper amount.

Mixer: It is the section where the concrete mixture is prepared. Concrete mixers can be stationary or mobile and have a variety of capacities.

Silo: These are the storage areas where cement and other dusty materials are stored. Silos can be of high capacity and used to store cement, limestone, sawdust, and other additives.

Control Room: It is the center where all components of the concrete plant are controlled. The amount of constituents of the concrete mix and the mixing ratios are set here.

Water Tank: It is employed to store the water used in the preparation of the concrete mix.

Pneumatic System: It is used to provide the air pressure needed for the transportation of the concrete mix.

Electricity and Generator System: It is necessary for the operation of all electrical components in the concrete batching plant.

These are just the basic components of a typical concrete batching plant, and concrete batching plants may have different characteristics depending on the needs of the project. However, the combination of these components allows to produce the concrete mix with high quality.