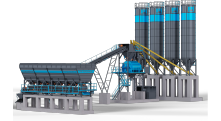

- Concrete Batching Plants

- Stationary Concrete Plant

- Mobile Concrete Plant

- Mini Concrete Batching Plant

- Compact Concrete Batching Plant

- Precast Concrete Batching Plant

- Concrete Mixer

STATIONARYConcrete Batching Plant

MOBILEConcrete Batching Plant

MINIConcrete Batching Plant

COMPACTConcrete Batching Plant

PRECASTConcrete Batching Plant

MIXERConcrete Mixer

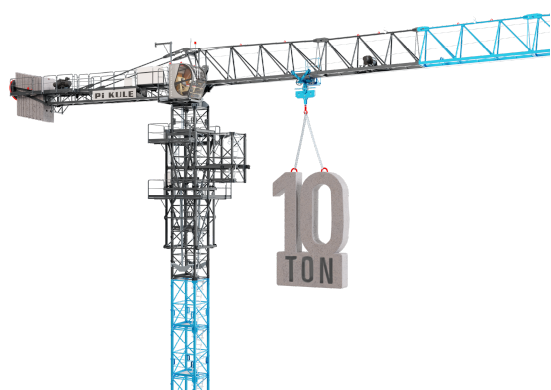

- Concrete Distribution Group

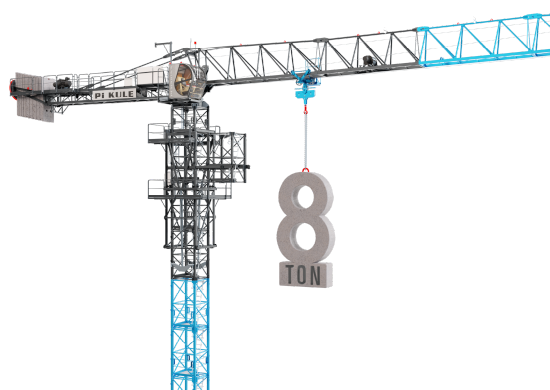

- Tower Crane

TOWER CRANE

10 Tons

TOWER CRANE8 Tons

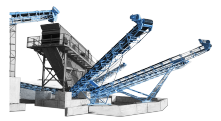

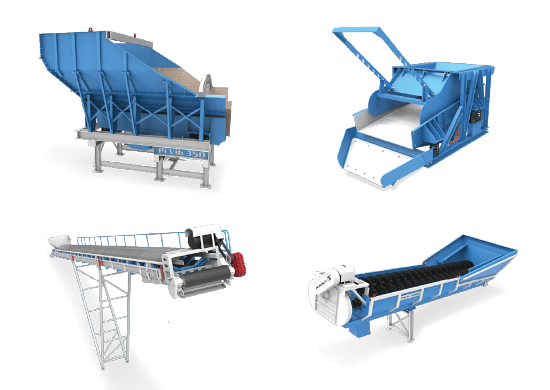

- Crushing Plant

CRUSHER

Crushing Plant

CRUSHING EQUIPMENTCrushing Plant

- Earth Moving Machine

MOTOR GRADER

Earth Moving Machine

BACKHOE LOADEREarth Moving Machine

English

Superior Features of Pi Makina Concrete Pumps

Pi Makina Concrete Pumps provide many advantages to the user compared to their competitors. Production technology is at the highest level compared to other domestic manufacturers. All the materials used are first tested and approved in the quality control laboratory and then go into production. Welded manufacturing is combined with expert certified welders and welding robots. Advanced stages of manufacturing, desired surface qualities are obtained with precision machining on 5-axis CNC benches.

The fasteners connecting the main parts of the Concrete Pump go through heat treatment applications in special furnaces. The manufacturing and assembly processes of hydraulic cylinders are carried out with the same care, and then pressure and tightness tests are carried out.

In addition to all these, all other spacers used are selected from the best quality brands in the world.

* Boom - sheet thickness - HARDOX 700

* Swing Group - BREVINI RIDUTTORI - METALLURGICA ROSSI S.P.A (ITALY)

* HYDRAULIC UNIT - PTO Group (Pump Drive Gear Unit) - OMSI (ITALY)

* Oil Cooler - EMMEGI (ITALY)

* Mixer motor and Swing hydraulic motor - SAM HYRAULIC (ITALY)

* Pressure Filter - REXTROTH (GERMANY)

* Swing Filter - HYDAC (GERMANY)

* HYDRAULIC OIL COOLER - EMMEGI (ITALY)

* Main Hydraulic Pump, Boom Pump, Tandem Pump - REXTROTH (GERMANY)

* Main Control / Cone Control / Safety Valves - REXTROTH (GERMANY)

* Front Rear Control / Mixer Valves - GALTECH (ITALY)

* Boom Control Valves / Piston Lock Valves - HAWE HYDRAULIC (GERMANY)

* Foot Release Adjustment Valve / Foot Lock Control - OLEOSTAR (ITALY)

* Remote Control System - HAWE HYDRAULIC (GERMANY)

* Automatic Lubrication- LINCOLN (USA)

The fasteners connecting the main parts of the Concrete Pump go through heat treatment applications in special furnaces. The manufacturing and assembly processes of hydraulic cylinders are carried out with the same care, and then pressure and tightness tests are carried out.

In addition to all these, all other spacers used are selected from the best quality brands in the world.

* Boom - sheet thickness - HARDOX 700

* Swing Group - BREVINI RIDUTTORI - METALLURGICA ROSSI S.P.A (ITALY)

* HYDRAULIC UNIT - PTO Group (Pump Drive Gear Unit) - OMSI (ITALY)

* Oil Cooler - EMMEGI (ITALY)

* Mixer motor and Swing hydraulic motor - SAM HYRAULIC (ITALY)

* Pressure Filter - REXTROTH (GERMANY)

* Swing Filter - HYDAC (GERMANY)

* HYDRAULIC OIL COOLER - EMMEGI (ITALY)

* Main Hydraulic Pump, Boom Pump, Tandem Pump - REXTROTH (GERMANY)

* Main Control / Cone Control / Safety Valves - REXTROTH (GERMANY)

* Front Rear Control / Mixer Valves - GALTECH (ITALY)

* Boom Control Valves / Piston Lock Valves - HAWE HYDRAULIC (GERMANY)

* Foot Release Adjustment Valve / Foot Lock Control - OLEOSTAR (ITALY)

* Remote Control System - HAWE HYDRAULIC (GERMANY)

* Automatic Lubrication- LINCOLN (USA)