Concrete Plant |

Pi 60 BP |

Pi 60 BPS |

Pi 100 BP |

Pi 100 BSP |

Pi 30-60 BP |

Pi 30-100 BP |

|---|---|---|---|---|---|---|

|

Capacity |

55-60 m³ |

55-60 m³ |

90-100 m³ |

90-100 m³ |

30-60 m³ |

30-120 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

Planetary |

Planetary |

Planetary |

Planetary |

|

Mixer Capacity |

1 m³ |

1 m³ |

2 m³ |

2 m³ |

0,5-1 m³ |

0,5-2 m³ |

Concrete Plant |

Pi 60 BP |

Pi 60 BPS |

|---|---|---|

|

Capacity |

55-60 m³ |

55-60 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

1 m³ |

1 m³ |

Concrete Plant |

Pi 100 BP |

Pi 100 BSP |

|---|---|---|

|

Capacity |

90-100 m³ |

90-100 m³ |

|

Mixer Type |

Planetary |

Planetary |

|

Mixer Capacity |

2 m³ |

2 m³ |

Concrete Plant |

Pi 30-60 BP |

Pi 30-100 BP |

|---|---|---|

|

Capacity |

30-60 m³ |

30-120 m³ |

|

Mixer Type |

Planetary |

Planetary |

|

Mixer Capacity |

0,5-1 m³ |

0,5-2 m³ |

Concrete Plant |

Pi 60 BP |

Pi 60 BPS |

Pi 100 BP |

Pi 100 BSP |

Pi 30-60 BP |

Pi 30-100 BP |

|---|---|---|---|---|---|---|

|

Capacity |

71-78 yrd³ |

71-78 yrd³ |

117-130 yrd³ |

117-130 yrd³ |

39-78 yrd³ |

39-156 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

Planetary |

Planetary |

Planetary |

Planetary |

|

Mixer Capacity |

1.3 yrd³ |

1.3 yrd³ |

2.6 yrd³ |

2.6 yrd³ |

0,65-1,3 yrd³ |

0,65-2.6 yrd³ |

Concrete Plant |

Pi 60 BP |

Pi 60 BPS |

|---|---|---|

|

Capacity |

71-78 yrd³ |

71-78 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

1.3 yrd³ |

1.3 yrd³ |

Concrete Plant |

Pi 100 BP |

Pi 100 BSP |

|---|---|---|

|

Capacity |

117-130 yrd³ |

117-130 yrd³ |

|

Mixer Type |

Planetary |

Planetary |

|

Mixer Capacity |

2.6 yrd³ |

2.6 yrd³ |

Concrete Plant |

Pi 30-60 BP |

Pi 30-100 BP |

|---|---|---|

|

Capacity |

39-78 yrd³ |

39-156 yrd³ |

|

Mixer Type |

Planetary |

Planetary |

|

Mixer Capacity |

0,65-1,3 yrd³ |

0,65-2.6 yrd³ |

Product Catalog

- Pi 100 BSP

- Pi 100 BP

- Pi 60 BP

- Pi 60 BPS

- Pi 30-100 BP

- Pi 30-60 BP

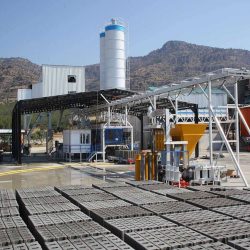

Pi 100 BPS ( 100 m³/h Capacity )

Pi 100 BSP, which can produce 100 m3 of concrete per hour and offers a flawless concrete mixture, has a bucket aggregate feeding system. The concrete batching plant offers you the quality of Pi Makina with its guarantee of trouble-free operation for many years. It is specially designed for projects that need high-capacity concrete in a shortage of space. Bucket Concrete Power Plant, which is designed taking into consideration the smallness of the area where the plant will be installed, is produced with the principle of providing perfect service for every need. The concrete batching plant, which has a planetary mixer of 2 m3, is also preferred in the production of precast, cobblestone and curbstone. Pi Makina compact concrete plants combine the fast and easy transportation feature with the robust strong structure of fixed concrete plants. In addition, compact plants with maximum safety measures are very easy to maintain. Pi 100 BSP concrete plant employs “the world's most advanced automation software” as in other models. Cobasys automation software developed by Pi Makina can also be configured according to the customer's needs.

Pi 100 BP ( 90-100 m³/h Capacity )

Pi 100BP concrete batching plant is a fixed concrete plant with belt and planetary mixer that can produce 90-100 m3 of concrete per hour. These plants, which are preferred in medium-sized projects where the plant will not be replaced, perform superiorly for many years. These concrete batching plants, designed with a belt aggregate conveying system, are also preferred for precast and concrete block practices with mold production lines thanks to the planetary mixer. Safety equipment on batching plants, which by design provides easy transportation and easy installation, provides a safe working environment. At the same time, by virtue of its wide platforms, these are the concrete pants for which the maintenance of mixer and other components is the easiest. Thanks to the software developed by Pi Makina used on the concrete plant, it is possible to obtain the entered prescription with low tolerance values. In addition, with its simple interface, many information such as the entire production, stock quantities, and customer records can be accessed from a single screen.

Pi 60 BP ( 60 m³/h Capacity )

Pi 60BP concrete batching plant is a fixed concrete plant with belt and planetary mixer that can produce 60 m3 of concrete per hour. These batching plants, which are preferred in small but non-relocatable projects, perform superiorly for many years. These concrete plants, designed with a belt aggregate conveying system, are also preferred for precast and concrete block applications having mold production lines by virtue of the planetary mixer. Safety equipment on power plants, which by design provides easy transportation and easy installation, provides a safe working environment. Moreover, thanks to its wide platforms, these are the concrete batching plants on which the maintenance of mixer and other components is the easiest. The software developed by Pi Makina used on the concrete plant ensures production exactly according to prescription with low tolerance values. In addition, with its simple interface, many data such as the entire production, stock quantities, and customer records can be accessed from a single screen.

Pi 60 BPS ( 60 m³/h Capacity )

Pi 60 BSP, which can produce 60 m3 of concrete per hour and offers a flawless concrete mixture, has a bucket aggregate feeding system. The concrete batching plant offers you the quality of Pi Makina with its guarantee of trouble-free operation for many years. It is specially designed for projects that need high-capacity concrete in a shortage of space. Bucket Concrete Power Plant, which is designed taking into consideration the smallness of the area where the plant will be installed, is produced with the principle of providing perfect service for every need. The concrete batching plant, which has a planetary mixer of 1 m3, is also preferred in the production of precast, cobblestone and curbstone. Pi Makina compact concrete plants combine the fast and easy transportation feature with the robust strong structure of fixed concrete plants. In addition, compact plants with maximum safety measures are very easy to maintain. Pi 60 BSP concrete plant employs “the world's most advanced automation software” as in other models. Cobasys automation software developed by Pi Makina can also be configured according to the customer's needs.

Pi 30-100 BP ( 120 m³/h Capacity )

As the first brand that comes to mind as far as precast and cobblestone concrete plants are concerned, the feature of Pi Makina Precast Concrete Plants that differentiates it from other concrete batching pants are double mixers built in on the main chassis. Pi 30-100BP has 2 planetary mixers, being 0.5 m³ and 2 m³, and has a capacity of 120 m3 per hour. Thanks to the design feature of planetary mixers, special types of concrete such as low or zero slump precast concrete, fiber additive concrete, self-settling concrete, and cobblestone concrete, etc. can be produced. One mixer of these plants, which is specially designed for the production of cobblestones, is connected to the cobblestone production machine, while the other mixer can be connected to trans mixers at the same time. The notable feature of Pi Makina’s concrete plant is that the automation system used in concrete plants is developed by Pi Makina. By virtue of this automation, the prescription entered to the machine is produced at low tolerance values. In addition, various data such as the entire production, stock quantities, and customer records can be accessed on single screen through its interface. It offers easy operation with its user-friendly interface and can be enhanced depending on the customer's request. Furthermore, Pi Makina precast concrete plants can operate being coupled with concrete distribution systems. By dint of the equipment that moves on the track with the concrete distribution system, the concrete produced can be poured to the desired point. This saves time and labor and increases efficiency in mold concrete casting.

Pi 30-60 BP ( 60 m³/h Capacity )

As the first brand that comes to mind as far as precast and cobblestone concrete plants are concerned, the feature of Pi Makina Precast Concrete Plants that differentiates it from other concrete batching pants are double mixers built in on the main chassis. Pi 30-60BP has 2 planetary mixers, being 0.5 m³ and 1 m³, and has a capacity of 60 m3 per hour. Thanks to the design feature of planetary mixers, special types of concrete such as low or zero slump precast concrete, fiber additive concrete, self-settling concrete, and cobblestone concrete, etc. can be produced. One mixer of these plants, which is specially designed for the production of cobblestones, is connected to the cobblestone production machine, while the other mixer can be connected to trans mixers at the same time. The notable feature of Pi Makina’s concrete plant is that the automation system used in concrete plants is developed by Pi Makina. By virtue of this automation, the prescription entered to the machine is produced at low tolerance values. In addition, various data such as the entire production, stock quantities, and customer records can be accessed on single screen through its interface. It offers easy operation with its user-friendly interface and can be enhanced depending on the customer's request. Furthermore, Pi Makina precast concrete plants can operate being coupled with concrete distribution systems. By dint of the equipment that moves on the track with the concrete distribution system, the concrete produced can be poured to the desired point. This saves time and labor and increases efficiency in mold concrete casting.

Outstanding Features

Installation and Operation

Minimum transport and installation time is required by dint of its superior design. With these features, the initial operating cost is very low.

Cost and Performance

With its erection in a short notice, it allows for immediate concrete pouring. It is remarkable with the sustainment of the same quality concrete pouring feature for years.

Safety and Maintenance

Due to its simple structure, ease of maintenance and safety of employees with all safety equipment on it are prioritized. Pi Makina quality makes a difference.

Automation and Use

Thanks to the special automation system developed by Pi Makina, it offers quality and serial concrete production. It provides easy operation with its user-friendly interface and remote connection feature.

Product Gallery

Erection/Transportation |

Pi 60 BP |

Pi 100 BP |

Pi 100 BSP |

Pi 30-60 BP |

Pi 30-100 BP |

|---|---|---|---|---|---|

|

Assembly Time  |

10 Day/Man |

10 Day/Man |

10 Day/Man |

10 Day/Man |

10 Day/Man |

|

Transport/Truck  |

3 Truck |

5 Truck |

5 Truck |

4 Truck |

5 Truck |

|

Container  |

3 Container |

4+1 Container + Open Top Container |

4+1 Container + Open Top Container |

2+2 Container + Open Top Container |

5+1 Container + Open Top Container |