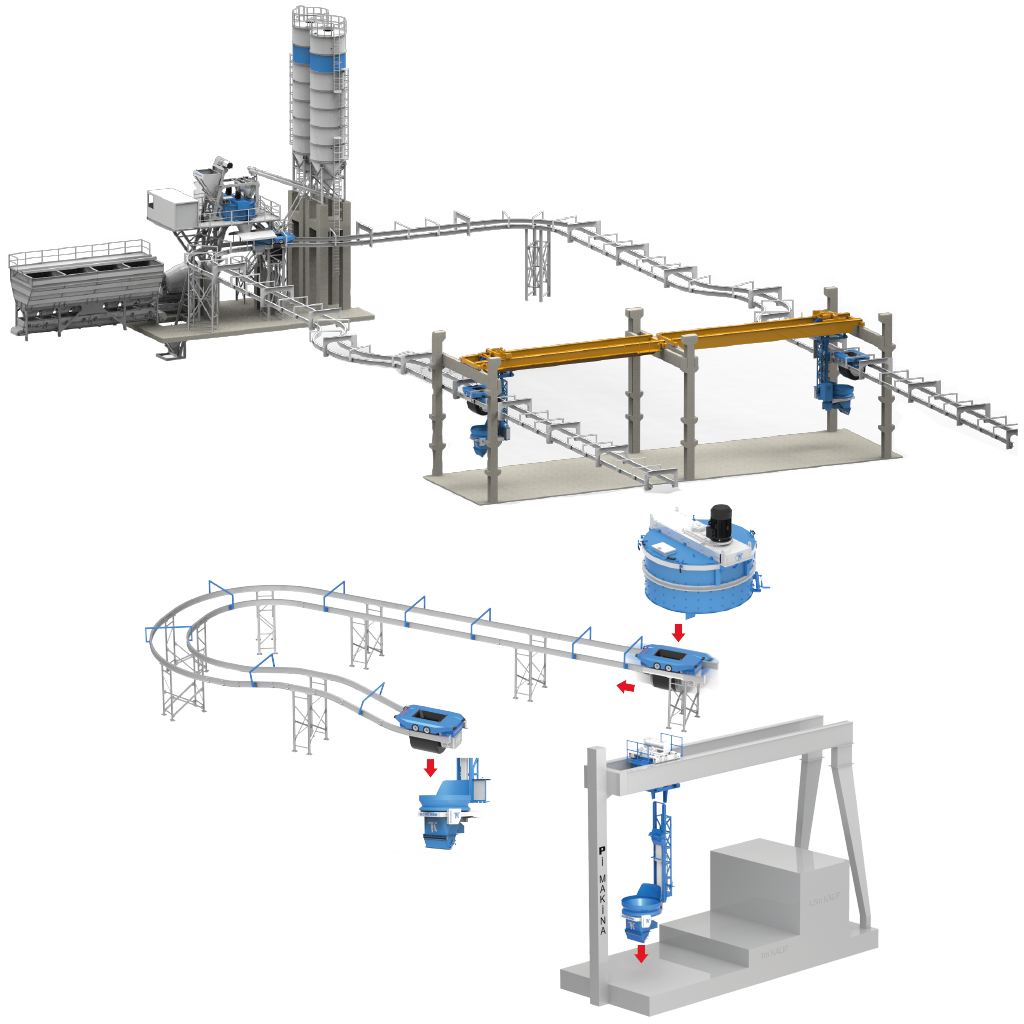

The concrete transport system is designed to increase efficiency and reduce costs in the production of prefabricated concrete elements (mold concrete). It was designed and developed by Pi Makina’s R&D center with TUBITAK support. In addition, the concrete transportation system, which has many advantages over its counterparts, is a project that has won an award by attaining the final stage in the Technology awards organized by TÜSIAD.

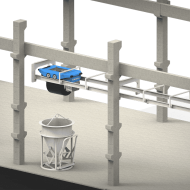

A rail line and a high-speed concrete transport hopper (Pi Fly) are used to deliver the concrete from the concrete plant to the molds. The concrete transported by the hopper is poured into molds with the casting unit (Pi Cast).

Pi Fly Pi Makina Concrete Distribution System, unlike traditional methods, is designed to achieve top-level efficiency using minimal labor. Developed based on the inspiration of technology and innovation, this system allows for fast and easy operation thanks to pre-prepared commands and one-button controlled operations. By virtue of this new technology, which is Turkey's first and only concrete distribution system, concrete prepared in the concrete batch plant can be transported at high speed with Pi FLY Concrete Conveyor Hoppers moving on the rail. With the help of the hopper, which allows 90-degree rotation and can ascend and descend, it provides great convenience and flexibility to the user in production areas. When used with the Pi CAST Concrete Discharge Hopper, the physical force required in the production area is reduced almost to zero. In Wet-Cast applications, through the use of Pi FLY and Pi CAST products collectively, concrete can be poured into molds much faster and much easier.

- Pi Fly

- Pi Cast

Pi Fly

An equipment that takes the concrete from the plant and transferring it to the desired point, moves at high and low speeds, is capable of going on straight and turning rail, can ascends and descends slopes, runs fully automatically and manually is capable of getting electricity off the rail.

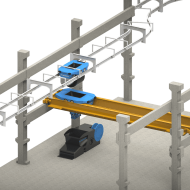

Pi Cast

This equipment takes the concrete from the concrete from the concrete transport hopper and pours it into the molds. It can rotate up-down, right-left and on its axis, and can work comfortably on axes, the portal can be integrated into the semi-portal or ceiling crane. It can attached and removed to and from the crane when starting work. It can be managed with a single control on the crane. It takes power from the crane.

Product Catalog

Pi Cast & Pi Fly |

Pi FLY 1000 |

Pi FLY 2000 |

Pi Cast 1000 |

Pi Cast 2000 |

|---|---|---|---|---|

|

Bunker Capacity |

1 m³ |

2 m³ |

1 m³ |

2 m |

Pi Cast & Pi Fly |

Pi FLY 1000 |

Pi FLY 2000 |

|---|---|---|

|

Bunker Capacity |

1 m³ |

2 m³ |

Pi Cast & Pi Fly |

Pi Cast 1000 |

Pi Cast 2000 |

|---|---|---|

|

Bunker Capacity |

1 m³ |

2 m |

Advantages of the system

- Faster production with fewer staff

- Monitoring and reporting all processes by computer

- More production

- Efficient use of the business area

- Easy operation

- Low operating cost owing to fewer machines

- Clean production

- Production with high safety

Product Gallery