- Home

- »

- Crushing and Screening Plant

Crushing and Screening Plant

Crushing and screening plants are used for crush and seperate the stones to the desired dimensions. These plants are used to produce aggregate to be used in constructions, highways, railways, asphalt and concrete plants. Stationary crushing plants are used for continuous and long-time projects, mobile crushing and screening plants are used for smaller and short-term projects.

Crushing and Screening process generally consists of 4 steps.

1- Coarse Crushing Process

After the material to be crushed is unloaded by truck, it is homogeneously loaded into the primary crushers/jaw crushers by the feeder. These equipments crushes the largest stones to one size smaller.

The crushed material is transported to other crushers by conveyor belts.

2- Medium and Fine Size Crushing Process

After the firts crushing process materials goes through a screen and then they are transported to the secondary crusher, jaw crusher with a belt conveyor for crushing. After that the crushed stones are sent to the screen again to bring the materials of various sizes.

3- Smallest Stone/Sand Making

The crushed stone is sent to a cone crusher, vertical shaft crusher or impact crusher (sand making machine) for further crushing and shaping and is reduced to its smallest size.

Step 4: Washing

If clean aggregate is desired, it is sent to the sand screws and the washing process is carried out.

CRUSHING PLANT EQUIPMENTS

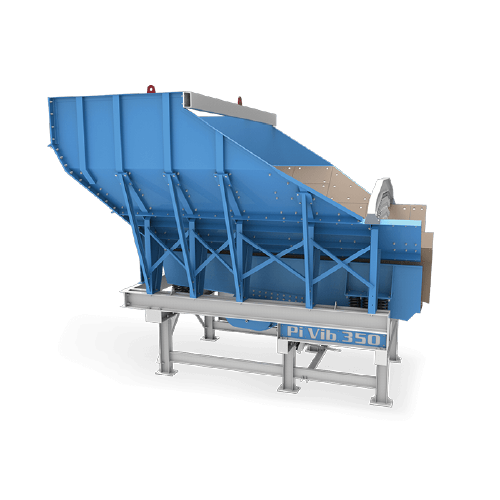

Feeders

In crushing/sifting plants, feeders are used to improve the capacity, adjust the size of materials fed to crushers and reduce maintenance costs. Pi Makina has been manufacturing vibrating feeders, dragline feeders and crawling feeders for use in crushing/sifting plants. These feeders are used to feed material out of the bunker and bin in a crushing/sifting plant.

Go to Page

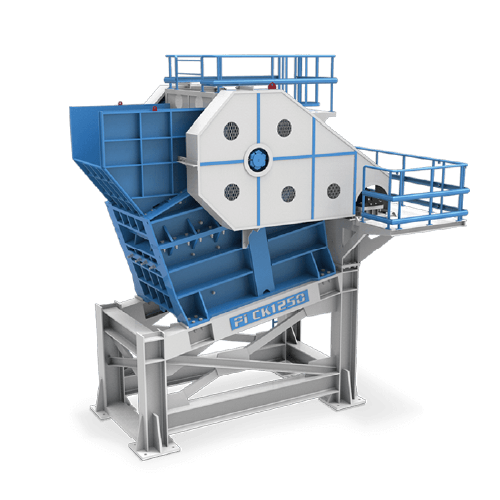

Crushers

Pi Makina has been using 4 types of crushers in crushing/screening plants: jaw crushers, impact crusher, vertical-shaft crusher and conical crushers. Crushers turn the material to harder and coarser grains or softer and smaller sizes, depending on its type and properties. Primary crushers are used to yield products of smaller grains like stone chips. Secondary crushers have a stationary structure and can be used to get materials of medium and low hardness. In plants where mobilization is important for purposes of functionality, mobile crushers are preferable. Vertical-shaft crushers have adjustable crushing jaws and come to the foreground with their capability of obtaining end-products of any size and its durability.

Go to Page

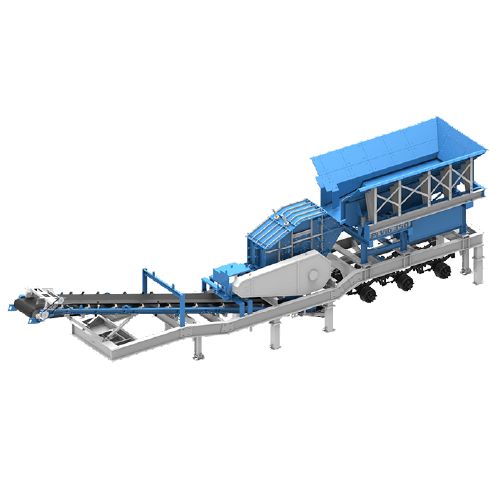

Mobile Crushers

Mobile crusher plants are used both for short-term projects and for small aggregate quarries. It is used in the mining industry, waste recycling works, and construction activities such as road construction. On the mobile crusher plants, there are equipment that can crush all kinds of materials such as impact, vertical shaft, jaw crushers.

Go to Page

Screens

Screens are one of the most important parts of a crushing/sifting plant and divided into two groups: stationary screens and mobile screens. Screens are selected as to the capacity for the material to be sifted, the moisture content and whether the sifting includes washing. Screens ensure that materials entering the primary crusher, secondary crusher, vertical-shaft crusher and mobile crusher are differentiated to desirable sizes. The Pi Makina screen products come to the foreground with the quality of material and technology used for them as well as their problem-free operation and durability for very many years.

Go to Page

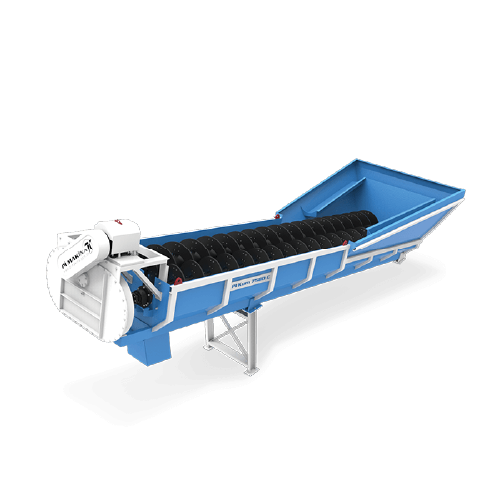

Sand Screw Washer

Sand spirals are manufactured with one single shaft or double shafts as to the requirements in mining operations and aggregates processing plants.

Go to Page

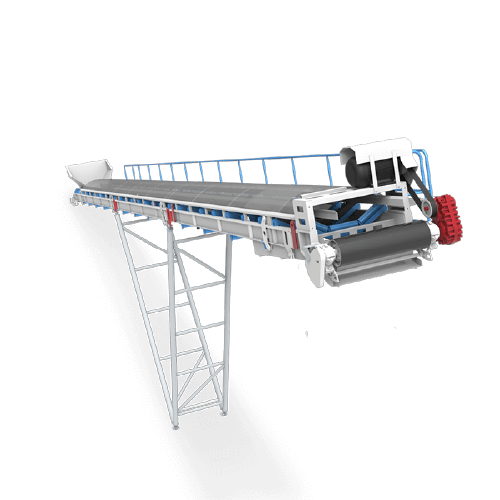

Belt Converyor

Belt conveyors ensure the conveyance of materials between other main equipments in concrete batching plants, mining operations and aggregates processing plants. In addition, Pi Makina manufactures single-shaft and double-shaft sand spirals.

Go to Page