Concrete Plant |

Pi 60 MTS |

Pi 100 MTS |

Pi 120 MTS |

Pi 60 MSP |

Pi 55 M-ECO |

|---|---|---|---|---|---|

|

Capacity |

50-60 m³ |

90-100 m³ |

90-100 m³ |

50-60 m³ |

50-55 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

Twin Shaft |

Planetary |

Single Shaft |

|

Mixer Capacity |

1 m³ |

2 m³ |

2 m³ |

1 m³ |

1 m³ |

Concrete Plant |

Pi 60 MTS |

Pi 100 MTS |

|---|---|---|

|

Capacity |

50-60 m³ |

90-100 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

1 m³ |

2 m³ |

Concrete Plant |

Pi 120 MTS |

Pi 60 MSP |

|---|---|---|

|

Capacity |

90-100 m³ |

50-60 m³ |

|

Mixer Type |

Twin Shaft |

Planetary |

|

Mixer Capacity |

2 m³ |

1 m³ |

Concrete Plant |

Pi 55 M-ECO |

|---|---|

|

Capacity |

50-55 m³ |

|

Mixer Type |

Single Shaft |

|

Mixer Capacity |

1 m³ |

Concrete Plant |

Pi 60 MTS |

Pi 100 MTS |

Pi 120 MTS |

Pi 60 MSP |

Pi 55 M-ECO |

|---|---|---|---|---|---|

|

Capacity |

65-78 yrd³ |

117-130 yrd³ |

117-130 yrd³ |

65-78 yrd³ |

65-71 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

Twin Shaft |

Planetary |

Single Shaft |

|

Mixer Capacity |

1,30 yrd³ |

2,60 yrd³ |

2,60 yrd³ |

1,30 yrd³ |

1,30 yrd³ |

Concrete Plant |

Pi 60 MTS |

Pi 100 MTS |

|---|---|---|

|

Capacity |

65-78 yrd³ |

117-130 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

1,30 yrd³ |

2,60 yrd³ |

Concrete Plant |

Pi 120 MTS |

Pi 60 MSP |

|---|---|---|

|

Capacity |

117-130 yrd³ |

65-78 yrd³ |

|

Mixer Type |

Twin Shaft |

Planetary |

|

Mixer Capacity |

2,60 yrd³ |

1,30 yrd³ |

Concrete Plant |

Pi 55 M-ECO |

|---|---|

|

Capacity |

65-71 yrd³ |

|

Mixer Type |

Single Shaft |

|

Mixer Capacity |

1,30 yrd³ |

Grand Mobile |

Pi 100 MB |

Pi 120 MCB |

Pi 100 MTS+ |

Pi 120 MTS+ |

|---|---|---|---|---|

|

Capacity |

90-100 m³ |

110-120 m³ |

90-100 m³ |

110-120 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

2 m³ |

3 m³ |

2 m³ |

3 m³ |

Grand Mobile |

Pi 100 MB |

Pi 120 MCB |

|---|---|---|

|

Capacity |

90-100 m³ |

110-120 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

2 m³ |

3 m³ |

Grand Mobile |

Pi 100 MTS+ |

Pi 120 MTS+ |

|---|---|---|

|

Capacity |

90-100 m³ |

110-120 m³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

2 m³ |

3 m³ |

Grand Mobile |

Pi 100 MB |

Pi 120 MCB |

Pi 100 MTS+ |

Pi 120 MTS+ |

|---|---|---|---|---|

|

Capacity |

117-130 yrd³ |

143-156 yrd³ |

117-130 yrd³ |

143-156 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

2,60 yrd³ |

3,90 yrd³ |

2,60 yrd³ |

3,90 yrd³ |

Grand Mobile |

Pi 100 MB |

Pi 120 MCB |

|---|---|---|

|

Capacity |

117-130 yrd³ |

143-156 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

2,60 yrd³ |

3,90 yrd³ |

Grand Mobile |

Pi 100 MTS+ |

Pi 120 MTS+ |

|---|---|---|

|

Capacity |

117-130 yrd³ |

143-156 yrd³ |

|

Mixer Type |

Twin Shaft |

Twin Shaft |

|

Mixer Capacity |

2,60 yrd³ |

3,90 yrd³ |

Product Catalog

- Pi 60 MTS

- Pi 100 MTS

- Pi 120 MTS

- Pi 60 MSP

- Pi 55 M-ECO

- Pi 100 MB

- Pi 120 MCB

- Pi 100 MTS+

- Pi 120 MTS+

Pi 60 MTS

Pi 60 M Mobile Concrete Batching Plant is preferred for short-term works with the capability to have all equipment on a single chassis. When the operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability to be re-erected in as little as 1 or 2 days and start concrete pour immediately. Pi 60M mobile concrete batching plant has a concrete capacity of 50-60 m3 per hour. In addition, it can mix any type of concrete smoothly and efficiently with a single shaft mixer of 1 m3 installed thereon.

Pi Makina Mobile Concrete Batching Plants are preferred for short-term projects with their compact structure and fast assembly and disassembly feature. It stands out with its use only by building a retaining wall without a need to cats foundation concrete. The robust structure, durability and concrete quality of fixed concrete plants combined with mobility have resulted in the most preferred type of power plant.

Pi Cobasys software developed by Pi Makina as an automation system and created entirely with customer feedback is used. With Cobasys, the most advanced automation system on the market, any kind of report can be obtained, and any adjustments related to the concrete plant can be easily made.

Pi 100 MTS

Pi 100 M Mobile Concrete Plant is preferred for short-term works with the ability to have all equipment on a single chassis. When the operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability to be re-erected in as little as 2 or 3 days and start concrete pour immediately. Pi 60M mobile concrete batching plant has a concrete capacity of 90-100 m3 per hour. In addition, it can mix any type of concrete smoothly and efficiently with a single shaft mixer of 2 m³.

Pi Makina Mobile Concrete Batching Plants are preferred for short-term projects with their compact structure and fast assembly and disassembly feature. It stands out with its use only by building a retaining wall without a need to cast foundation concrete. The robust structure, durability and concrete quality of fixed concrete plants combined with mobility have resulted in the most preferred type of batching plant.

Pi Cobasys software developed by Pi Makina as an automation system and created entirely with customer feedback is used. With Cobasys, the most advanced automation system on the market, any kind of report can be obtained and any adjustments related to the concrete plant can be easily made.

Pi 120 MTS

Pi 120 MB mobile concrete batching plant has a concrete capacity of 120-130 m3 per hour. Unlike other mobile concrete plants, it is the mobilized version of fixed concrete plants with separate aggregate bunker and separate feed belt conveying. Thanks to its mobile structure, when its operation is completed in any project, it can be disassembled immediately and moved to another project with the help of a tow truck. Pi 120MCB mobile concrete batching plant has a 3 m3 dual shaft mixers and works efficiently in the production of many special concretes such as ready-mix concrete, precast concrete, RCC concrete and heavy concrete.

Due to the fact that the Pi 120 MCB mobile concrete plant has a holding bunker and a separate aggregate bunker, there is no decrease in its capacity. Only the retaining wall to feed the aggregate and pouring concrete to the necessary places are enough for the mobile concrete plant to operate. P

Pi Cobasys software developed by Pi Makina as an automation system and created entirely with customer feedback is used. With Cobasys, the most advanced automation system on the market, any kind of report can be obtained and any adjustments related to the concrete plant can be easily made.

Pi 60 MSP

Pi 60 MSP Pi is one of the latest economic concrete batching plants of the product line ultimately released by Pi Makina. It is a lighter, more efficient and more affordable mobile concrete plant with lower investment costs compared to other mobile concrete plants. It is preferred for short-term work with the capability to have all the equipment on a single chassis. When its operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability of being re-erected in as little as 1 or 2 days and of starting concrete pour immediately. Pi 60 MSP mobile concrete batching plant has a concrete capacity of 50-60 m3 per hour. In addition, it can mix any type of concrete smoothly and efficiently with a single shaft mixer of 1 m3 installed thereon.

Pi Makina Mobile Concrete Plants are preferred for short-term projects with their compact structure and fast assembly and disassembly feature. It stands out with its use only by building a retaining wall without the need to cast a foundation concrete. The robust structure, durability and concrete quality of fixed concrete plants combined with the mobility have resulted in the most preferred type of concrete batching plant.

It employs Pi Cobasys software developed by Pi Makina as an automation system and created entirely with customer feedback. With Cobasys, the most advanced automation system on the market, any kind of report can be obtained and any adjustments related to the concrete plant can be easily made.

Pi 55 M-ECO

Pi 55 M-ECO Pi is one of the latest economic concrete batching plants of the product line ultimately released by Pi Makina. It is a lighter, more efficient and more affordable mobile concrete plant with lower investment costs compared to other mobile concrete plants. It is preferred for short-term work with the capability to have all the equipment on a single chassis. When its operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability of being re-erected in as little as 1 or 2 days and of starting concrete pour immediately. Pi 55 M-ECO mobile concrete batching plant has a concrete capacity of 50-55 m3 per hour. In addition, it can mix any type of concrete smoothly and efficiently with a single shaft mixer of 1 m3 installed thereon.

Pi Makina Mobile Concrete Plants are preferred for short-term projects with their compact structure and fast assembly and disassembly feature. It stands out with its use only by building a retaining wall without the need to cast a foundation concrete. The robust structure, durability and concrete quality of fixed concrete plants combined with the mobility have resulted in the most preferred type of concrete batching plant.

It employs Pi Cobasys software developed by Pi Makina as an automation system and created entirely with customer feedback. With Cobasys, the most advanced automation system on the market, any kind of report can be obtained and any adjustments related to the concrete plant can be easily made.

Pi 100 MB

Pi 100 MB Pi is one of the latest economic concrete batching plants of the product line ultimately released by Pi Makina. It is a lighter, more efficient and more affordable mobile concrete plant with lower investment costs compared to other mobile concrete plants. It is preferred for short-term work with the capability to have all the equipment on a single chassis. When its operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability of being re-erected in as little as 1 or 2 days and of starting concrete pour immediately.

Pi 120 MCB

Pi 120 MCB Pi is one of the latest economic concrete batching plants of the product line ultimately released by Pi Makina. It is a lighter, more efficient and more affordable mobile concrete plant with lower investment costs compared to other mobile concrete plants. It is preferred for short-term work with the capability to have all the equipment on a single chassis. When its operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability of being re-erected in as little as 1 or 2 days and of starting concrete pour immediately.

Pi 100 MTS+

Pi 100 MTS+ Pi is one of the latest economic concrete batching plants of the product line ultimately released by Pi Makina. It is a lighter, more efficient and more affordable mobile concrete plant with lower investment costs compared to other mobile concrete plants. It is preferred for short-term work with the capability to have all the equipment on a single chassis. When its operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability of being re-erected in as little as 1 or 2 days and of starting concrete pour immediately.

Pi 120 MTS+

Pi 120 MTS+ Pi is one of the latest economic concrete batching plants of the product line ultimately released by Pi Makina. It is a lighter, more efficient and more affordable mobile concrete plant with lower investment costs compared to other mobile concrete plants. It is preferred for short-term work with the capability to have all the equipment on a single chassis. When its operation is completed, it can be shipped only with a single tow truck for use in another project. It has the capability of being re-erected in as little as 1 or 2 days and of starting concrete pour immediately.

Outstanding Features

Installation and Operation

Minimum transport and installation time is required by dint of its superior design. With these features, the initial operating cost is very low.

Cost and Performance

With its erection in a short notice, it allows for immediate concrete pouring. It is remarkable with the sustainment of the same quality concrete pouring feature for years.

Safety and Maintenance

Due to its simple structure, ease of maintenance and safety of employees with all safety equipment on it are prioritized. Pi Makina quality makes a difference.

Automation and Use

Thanks to the special automation system developed by Pi Makina, it offers quality and serial concrete production. It provides easy operation with its user-friendly interface and remote connection feature.

Product Gallery

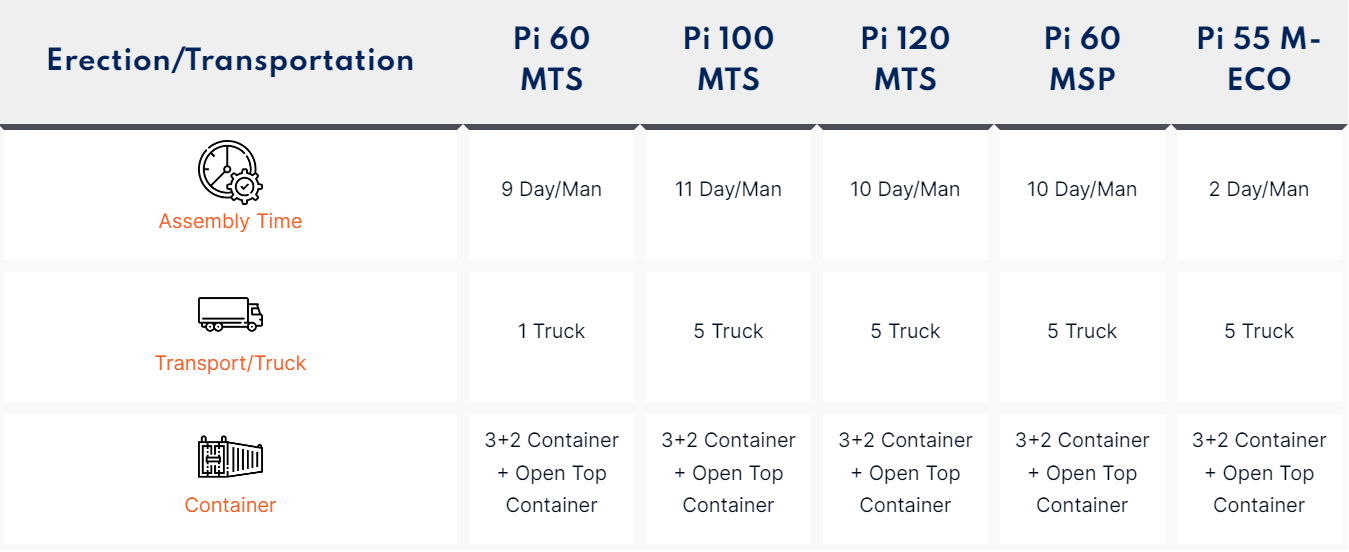

Erection/Transportation |

Pi 60 MTS |

Pi 100 MTS |

Pi 120 MTS |

Pi 60 MSP |

Pi 55 M-ECO |

|---|---|---|---|---|---|

|

Assembly Time  |

9 Day/Man |

11 Day/Man |

10 Day/Man |

10 Day/Man |

2 Day/Man |

|

Transport/Truck  |

1 Truck |

5 Truck |

5 Truck |

5 Truck |

5 Truck |

|

Container  |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |

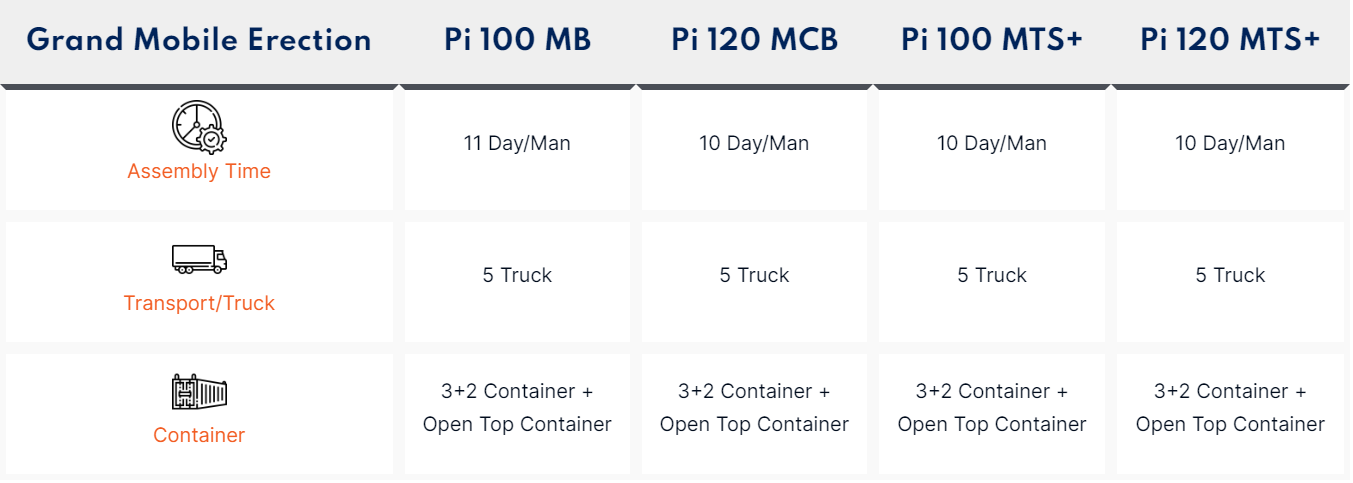

Grand Mobile Erection |

Pi 100 MB |

Pi 120 MCB |

Pi 100 MTS+ |

Pi 120 MTS+ |

|---|---|---|---|---|

|

Assembly Time  |

11 Day/Man |

10 Day/Man |

10 Day/Man |

10 Day/Man |

|

Transport/Truck  |

5 Truck |

5 Truck |

5 Truck |

5 Truck |

|

Container  |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |

3+2 Container + Open Top Container |